Listertube invests in electric multi-stack machine

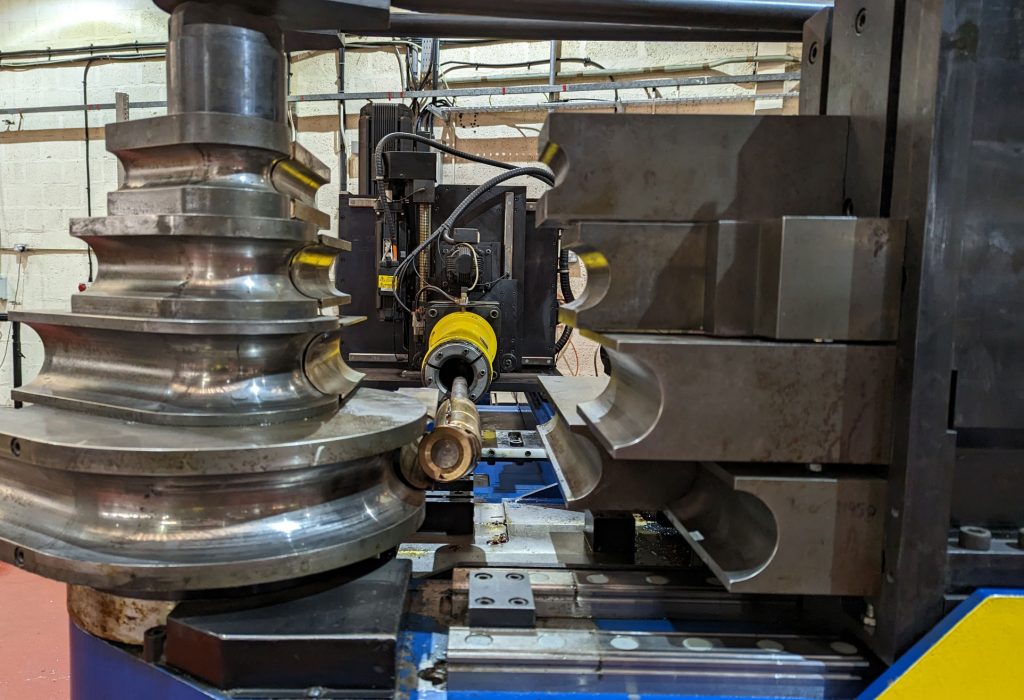

Listertube is proud to announce the addition of a Unison Breeze 76 multi-stack machine, which will allow for multiple tooling sets to be mounted.

As a multi-stack machine, the Unison Breeze 76 permits for different bend radii, typically up to five, on the same tube component. In order to produce complex tube parts, compound bending takes place on the machine, which is when two bends are close enough together that there is no straight clamping space between them.

With the Unison 76, we can produce tooling spanning multiple stacks to cater for this type of complex component. In addition, one of the tool stack spaces can be used for a ring roller setup, which allows for large radius bending.

The machine is also fitted with push assist, meaning Listertube can produce much tighter bend radii than on a usual basis, e.g. down to one times tube diameter, on large diameter tubes.

Energy efficiencies drive Listertube’s sustainability goals

As an all-electric machine, the Unison Breeze 76 is considerably more energy efficient than traditional bending machines, helping Listertube in its commitment to reducing its carbon footprint wherever it can.

As a four-stack machine, this means we can bend tubes with up to four different radii bends (subject to tooling), which will significantly increase Listertube’s capabilities. Staff training has now taken place on the machine, meaning we are now able to pass the efficiencies onto our customers.

In summary, this machine acquisition enables us to now bend up to 3” or 76mm tube, with complex bend radii varying from less than 2D up to large arcs, all on the same product, thereby increasing speed of delivery and efficiency.

For more information on Listertube, please follow us on LinkedIn.